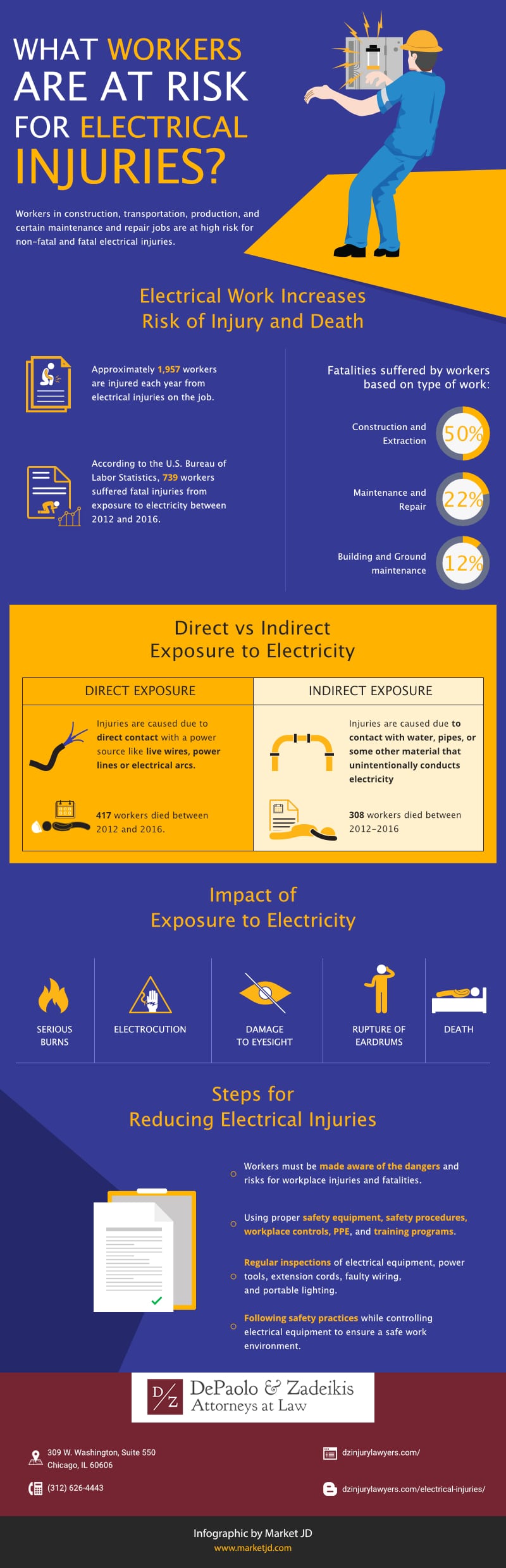

What Workers Are at Risk for Electrical Injuries?

Electrical injuries are a serious hazard in many workplaces. From electricians and construction crews to manufacturing and maintenance teams, thousands of workers are injured by electrical exposure each year. Understanding which workers face the highest risks and how those risks can be reduced is essential to improving safety on the job.

(Article continues below infographic)

______

Table of Contents

Why Electrical Injuries Are So Dangerous

Electricity can cause life-changing injuries in seconds. Severe burns, electrocution, hearing loss, and internal organ damage are among the possible outcomes of electrical contact. The danger is not limited to electricians. Anyone working near electrical systems, tools, or live wiring may be at risk.

According to the U.S. Bureau of Labor Statistics, over 2,300 workers suffer electrical injuries each year, and hundreds lose their lives from exposure to electricity. Many of these incidents occur in occupations that involve construction, extraction, and repair work.

Even when an electrical injury is not fatal, it can lead to lasting damage. Some victims suffer severe nerve damage, chronic pain, muscle weakness, or cardiac complications. In many cases, recovery requires long hospital stays, physical therapy, and time away from work. These injuries can affect a worker’s health and their ability to earn a living and support their family.

High-Risk Industries for Electrical Accidents

Although electrical hazards can exist in almost any workplace, some industries see higher injury and fatality rates than others.

- Construction and Extraction: These workers account for about half of all fatal electrical injuries. Contact with power lines, unfinished wiring, and faulty tools are common hazards.

- Maintenance and Repair: Workers who service electrical systems or equipment often encounter live wires or malfunctioning components.

- Building and Grounds Maintenance: Even routine maintenance can expose workers to electricity through damaged cords or wet surfaces.

Manufacturing, transportation, and utility workers are also exposed to high voltage and complex electrical systems on a daily basis. Electricians, HVAC technicians, and power line workers are especially vulnerable because their jobs require them to work directly with energized equipment.

Outdoor work presents additional risks. Wet or humid conditions, overhead power lines, and metal ladders can increase the chance of electrical contact. Even a simple task like trimming a tree or cleaning an exterior light fixture can become dangerous if proper precautions are not taken.

Direct vs. Indirect Exposure to Electricity

Electrical exposure can happen in two ways.

- Direct Exposure: This occurs when a worker makes physical contact with a live electrical source such as a wire, power line, or arc flash.

- Indirect Exposure: This happens when a worker touches a conductive material such as water, metal pipes, or tools that carry an electrical current unintentionally.

Direct contact often results in the most serious injuries because the current passes through the body. Indirect exposure is also hazardous and can happen when water or metal conducts electricity from a nearby source. Both types of exposure can cause severe injury or death if safety procedures are ignored.

Preventing Electrical Injuries in the Workplace

Employers and workers can take several important steps to prevent electrical injuries.

- Follow OSHA Safety Standards: OSHA requires specific safety practices for electrical work, including the use of insulated tools, proper grounding, and lockout/tagout procedures to prevent accidental energization.

- Use Personal Protective Equipment (PPE): Insulated gloves, boots, and safety goggles reduce the risk of shock and burns. Workers should also wear flame-resistant clothing when working near live circuits.

- Provide Regular Training: Workers should learn how to identify hazards, report unsafe conditions, and respond to electrical emergencies. Refresher courses help reinforce safe habits.

- Inspect Equipment Frequently: Routine inspections of power tools, extension cords, and wiring can reveal damage before it causes an accident.

- Create a Culture of Safety: Employers should encourage open communication about hazards, promote near-miss reporting, and reward safe practices.

Good housekeeping also matters. Keeping cords organized, cleaning up spills, and maintaining dry work areas can greatly reduce electrical risks. Workers should never use damaged tools or operate equipment in wet environments unless it is specifically rated for that use.

Common Situations That Increase the Risk of Electrical Injury

Even in industries with strict safety standards, many day-to-day work activities can expose employees to electrical hazards. Understanding when and where these risks are most likely to occur can help reduce accidents before they happen.

1. Working Near Overhead or Buried Power Lines

Construction crews, utility workers, and landscapers often work near live electrical lines. Accidental contact with an overhead power line is one of the leading causes of electrical fatalities. Similarly, digging without checking for buried lines can result in severe shocks or explosions. Every job site should be surveyed for potential contact points before work begins.

2. Using Damaged Tools or Cords

Power tools, extension cords, and electrical panels can wear down over time. Frayed insulation, cracked plugs, or exposed wires can easily energize surrounding metal or surfaces. Workers should always inspect equipment before use and immediately remove damaged tools from service.

3. Working in Wet or Humid Environments

Water is a powerful conductor of electricity. Jobs performed outdoors, in basements, or near plumbing systems can become dangerous if moisture comes into contact with energized equipment. Employers should provide ground fault circuit interrupters (GFCIs) and make sure all electrical gear is rated for wet conditions.

4. Improper Lockout or Tagout Procedures

Maintenance workers often service electrical machinery that must be shut down before repairs. If a circuit is re-energized unexpectedly, the worker can be seriously injured. OSHA requires employers to establish clear lockout/tagout procedures that prevent equipment from starting while it is being worked on.

5. Lack of Training or Awareness

One of the most preventable causes of electrical injury is insufficient training. Workers who do not understand how to recognize or avoid electrical hazards are far more likely to be injured. Regular safety meetings, certification courses, and refresher sessions can dramatically lower the risk of accidents.

6. Overloaded Circuits and Poorly Maintained Systems

Electrical systems that are not maintained properly can overheat or short-circuit. Overloaded circuits, outdated wiring, and makeshift repairs all increase the chance of sparks, fires, and shocks. Preventive maintenance and professional inspections are essential in high-risk workplaces.

FAQs About Electrical Injuries at Work

What are the most common causes of electrical injuries?

Faulty wiring, contact with overhead power lines, improper grounding, and lack of PPE are leading causes.

Who is most at risk of electrical injuries?

Construction workers, electricians, maintenance staff, and industrial technicians face the highest risks.

Can I file a claim for an electrical injury at work?

Yes. Most workers are covered by workers’ compensation, but in some cases, a third party (such as a contractor or equipment manufacturer) may also be liable.

Speak With a Chicago Electrical Injury Lawyer

If you or someone you love suffered an electrical injury at work, let us help you recover compensation. Call 312-263-7560 for a free consultation.